Smart Lean: Eliminating Overproduction with AI

How Service Operations Can Target Overproduction by Merging Lean Discipline with AI Execution

In Lean methodology, overproduction refers to producing more than what is needed or producing it too early. For service operations, this waste manifests as unnecessary reports, redundant communications, or services delivered before the customer requires them. Such overproduction creates friction, cost, and customer dissatisfaction.

In today's digital era, where services are often automated and data-driven, overproduction can occur rapidly and at scale. Addressing this waste requires integrating Lean principles with advanced technologies like Artificial Intelligence (AI) to ensure services align precisely with customer demand.

Traditional Lean Approach

Historically, service organizations have employed various Lean tools to identify and mitigate overproduction:

Value Stream Mapping (VSM): Helps visualize the flow of services and identify steps that do not add value or are performed prematurely.

Standard Work: Establishes consistent procedures to prevent unnecessary variations that can lead to overproduction.

Visual Management: Utilizes dashboards and indicators to monitor service levels and flag potential overproduction.

While effective, these methods often lack the real-time responsiveness needed in our fast-paced digital world.

“Establish Pull” refers to designing a workflow where work is initiated based on actual customer demand, not forecasts or arbitrary schedules.

How AI Transforms Overproduction

True operational excellence doesn’t come from simply adding technology to outdated processes. It comes from rethinking how and when value is delivered. AI enables this shift by helping service teams avoid doing too much, too soon. Rather than reacting or overdelivering, teams can act precisely when needed.

Below are six AI tools that drive this transformation by reducing service overproduction through smarter timing, personalization, and process alignment.

Predictive Analytics

Forecasts customer demand to schedule services just-in-time.

Limitation: Depends on data quality; struggles in volatile environments.

Mitigation: Combine with expert oversight and ensemble modeling.

Natural Language Processing (NLP)

Analyzes interactions to decide when communication is truly needed

Limitation: Can misread nuance or sarcasm.

Mitigation: Use domain-specific fine-tuning and escalate edge cases to human review.

Chatbots & Virtual Assistants

Handle basic inquiries and reduce early or excessive human involvementv

Limitation: Limited to pre-programmed flows.

Mitigation: Escalate to humans based on sentiment and intent detection.

Machine Learning (ML)

Learns from historical data to optimize when and how services are delivered

Limitation: Opaque "black box" logic.

Mitigation: Use explainable AI (XAI*); start with pilot use cases.

XAI: AI systems designed to make their decisions and reasoning transparent and understandable to humans.

Human-Centered Design

Aligns AI output with real-world user behaviors

Limitation: Poor design can create confusion or extra steps.

Mitigation: Prototype with end-users; validate through observation.

Agentic AI

Autonomous agents trigger tasks only when needed

Limitation: Still maturing; integration with legacy tools may be complex.

Mitigation: Deploy in low-risk workflows with clear governance.

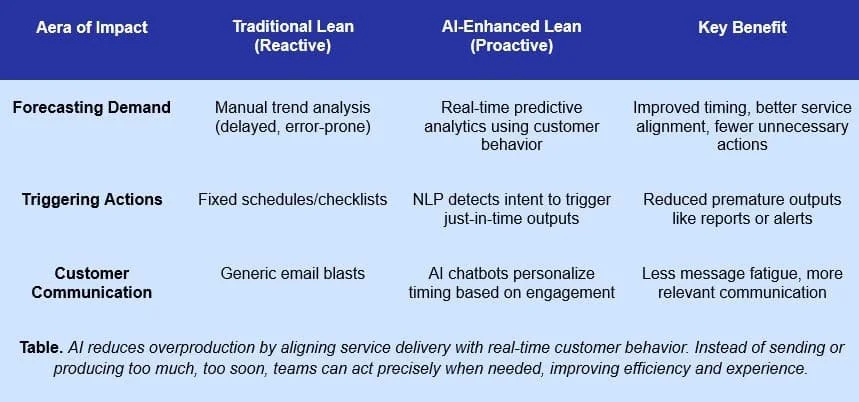

Traditional Lean vs. AI-Enhanced Lean

These examples demonstrate how AI shifts service delivery from reactive and scheduled outputs to just-in-time and customer-aligned actions eliminating the invisible costs of doing too much, too early.

AI in the Customer Journey

The alignment of service actions with real customer behavior becomes especially powerful when viewed through the lens of the customer journey.

Consider an online insurance provider offering self-service quote tools. As soon as a user enters their basic details but abandons the process before submitting, the system automatically triggers a series of daily reminders, follow-up calls, and promotional emails.

The problem: The customer hasn’t yet shown a clear intent to buy. These untimely and repetitive actions create digital clutter, frustrate prospects, and drain internal resources (classic symptoms of overproduction in service delivery).

By applying AI:

Behavioral models analyze customer actions (e.g., time spent on the quote page, fields completed, click patterns).

Predictive analytics determine the likelihood of conversion and recommend the ideal moment to re-engage.

Communications are tailored and delayed until meaningful signals of intent appear.

The result: More relevant touchpoints, less friction, and better conversion, all while eliminating unnecessary effort. The company moves from pushing information to delivering value precisely when the customer is ready.

Measuring the Impact: Unused Outputs as a KPI

Overproduction in services rarely sets off alarms. Unread reports still get built. Emails no one requested still get sent. Dashboards pile up even if no one logs in.

To expose this silent overload, track Unused Reports / Outputs. This KPI measures how many reports, emails, or dashboards are created but never accessed, read, or used by their intended audience (employees, managers, or customers). It reveals the time and effort spent producing work that adds no value.

In many organizations, 30 to 50% of reports go unused. If your analytics show similar patterns, you're not just informing, you're overproducing.

Navigating the AI-Lean Journey

Best Practices

Train staff early: Adoption starts with readiness. Don’t expect AI to “just work.”

Use ensemble models*: Combining models improves resilience and reduces risk from bad predictions.

Pilot explainable AI (XAI): Start small and make sure stakeholders understand what the AI is doing.

Secure leadership buy-in: AI-enabled Lean projects need visible sponsorship to succeed.

* Machine learning techniques that combine multiple models to produce better, more reliable results than any single model alone.

Pitfalls to Avoid

Overtrusting AI: Always validate AI output with operational or customer feedback.

Siloed data: Fragmented or poor-quality data will sabotage predictions.

Deploying prematurely: Rushing AI implementation without redesigning the process leads to automation of waste.

Weak oversight: AI is not “set and forget”—it needs governance, retraining, and ongoing tuning.

Avoiding these pitfalls is as crucial as the technology itself. A Lean-AI integration strategy should always include governance, iteration, and continuous feedback loops.

Real-World Example

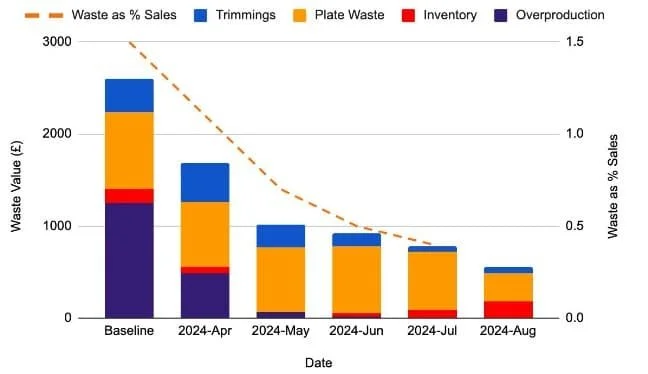

How London Marriott Cut Food Waste by 67% (Saving £14K Annually)

In the hospitality industry, overproduction and food waste are persistent challenges, often stemming from inefficient kitchen operations and a lack of real-time data. The London Marriott Hotel Canary Wharf tackled this issue head-on by partnering with Winnow, an AI-powered food waste reduction platform, achieving a 67% reduction in food waste within just six months. This success story exemplifies how Smart Lean combining Lean principles with AI-driven insights can eliminate overproduction waste while boosting sustainability and profitability.

Key Achievements:

67% reduction in food waste – Equivalent to 8 tons annually.

£14,000 (US19,000) saved per year – Reduced food purchasing costs.

33 tons of CO₂e eliminated – Contributing to Marriott’s Mission Zero net-zero emissions goal.

20,000 meals saved – Redirecting surplus food creatively.

How AI Drove Leaner Operations:

Data-Driven Decision Making

Winnow’s analytics platform provided real-time insights into waste patterns, enabling chefs to adjust portion sizes and buffet offerings (e.g., smaller containers post-10 AM).

Executive Chef Sanjay Jadhav noted that daily reports helped identify trends and optimize menu planning.

Mindset Shift & Cross-Department Collaboration

Waste reduction became a shared goal, fostering innovation across teams.

Initiatives included edible wheatgrass plates, upcycled coffee scrubs, and sugarcane-based water bottles.

3. Creative Zero-Waste Cooking

Surplus ingredients were transformed into new dishes, such as:

Shakshuka (using vegetable trimmings and leftover eggs).

Bread and Butter Pudding (made from unused pastries and surplus milk).

The Bigger Picture:

This case study demonstrates how AI enhances Lean methodologies by:

Pinpointing waste sources with precision.

Empowering teams to act on data, not guesswork.

Turning waste reduction into a creative, cost-saving opportunity.

For businesses aiming to cut waste and improve margins, the lesson is clear: Smart Lean isn’t just about doing less, it’s about using AI to do better.

Source: Winnow Solutions

Action Plan

To address overproduction using AI in your service organization:

Assess Current Processes: Utilize Value Stream Mapping to identify areas of overproduction.

Collect and Analyze Data: Gather data on customer interactions, service delivery times, and demand patterns.

Implement AI Tools: Deploy AI solutions like predictive analytics and NLP to forecast demand and optimize service delivery.

Monitor and Adjust: Continuously monitor AI outputs and adjust processes to ensure alignment with customer needs.

Train Staff: Educate employees on new technologies and processes to ensure smooth integration and adoption.

Conclusion

Combining Lean principles with AI technologies offers a powerful approach to eliminating overproduction in service operations. By aligning services closely with actual customer demand, organizations can enhance efficiency, reduce costs, and improve customer satisfaction.

Ultimately, integrating AI into Lean is not just about optimization, it’s about delivering customer value with speed, clarity, and purpose, while fostering a culture of continuous improvement.

@ 2025 Lean Bizness Inc. | Strategy Through Execution

Based in North America | Working with clients across North America and internationally

[ Privacy Policy ] [ Terms of Use ]